Tailored Solutions On-Demand

Tailored epitaxial solutions allow customers to design and customize epitaxial solutions, based on individual technical requirements.

Customizing your epitaxial solutions

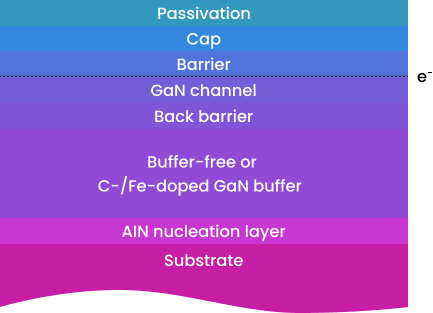

SweGaN offers tailored epitaxial solutions on-demand to address specific technical challenges and fulfill bespoke requirements. Creating customized epitaxial solutions starts by selecting from a range of substrates and options for Buffer, Barrier, Cap, Passivation and Back Barrier.

Reach out to our specialists to explore additional customization options based on your needs.

Customization

SUBSTRATE

- 3’’/4’’/6’’ SiC

- GaN

- Sapphire

- Silicon

Buffer

The conventional Fe-doped or C-doped buffer layer offers great compatibility with existing RF/power transistor technologies. Our unique buffer-free epitaxial solutions enable exceptional device performance and reliability without noticeable trade-offs.

- Buffer-free (channel)

- Fe-doped buffer

- C-doped buffer

Barrier

The barrier layer not only induces the channel electrons (e–), but also serves as a critical layer that defines the transistor technology. We provide a wide range of barrier layers for different transistor technologies.

Options:

- AlGaN

- AIN

- InAIN

- InAIGaN

Cap

The cap is typically a thin GaN layer, which alleviates the oxidation of the barrier, improving the reliability of the devices. For normally-off devices, a thick GaN layer is needed with Mg-doping to fully deplete the channel electrons.

- UID GaN

- Mg-doped GaN

Passivation

- In-situ SiNx

- Ex-situ SiNx

BACK Barrier

The back layer is typically employed in a HEMT structure for highly scaled devices to further improving the electron confinement and minimizing the short channel effects.

- AlGaN

- Al(Ga)N/Ga(Al)N superlattice

Reach out to discuss your technical needs and learn more Tailored Solutions On-Demand from SweGaN’s experts